F7205U-T Series UV Laser Machine

PRODUCT INTRODUCTION

Thermal transfer coding (TTO) is widely used in flexible packaging, but in high-speed, high-intensity production, issues like frequent line stops for ribbon replacement and frequent printhead maintenance often hinder efficiency. The FASTJET F7205U-T series UV laser coders emerge, offering the composite packaging industry a more efficient, low-maintenance, non-contact coding solution, effectively breaking through traditional process limitations.

PRODUCT FEATURES

Specialized for Laminated Packaging.

Zero consumables, reducing both resource consumption and cost.

Non-contact printing technology,safer and more reliable printing.

No need to replace the printhead.

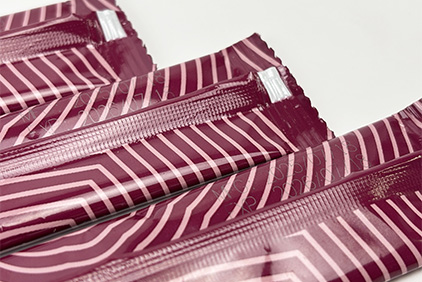

PRINTING EFFECTS

PRODUCT PARAMETERS

Technical Parameters

| F7205U-T Configuration and Parameters | |

| Laser types and characteristics | Main Materials: Anodized aluminum oxide structure + stainless steel Laser tube: Nanosecond UV laser generator Wavelength: 355 nm Cooling system: water-cooled (integrated) Positioning : UV positioning and infrared assisted focusing |

| Applications/Substrates | It is especially suitable for production lines that are using Thermal Transfer Overprinters (TTO). Flexible PCB Plastics (PE, PVC, PP, PS, POM, PC, acrylic, nylon, etc.) Metals (stainless steel, aluminum, gold, platinum, silver, titanium, brass, etc.) Wood (medium-density fiberboard, plywood, and fiberboard, etc.) Glass* |

| Speed(static marking or flying marking) | Marking speed of the scan head: up to 12000mm/second* Production line speed: up to 250m/min* |

| Marking characteristics | Number of lines marked: limited only by character height and markable area Standard industrial fonts (Windows®TrueType®) and single-line fonts, machine-readable codes (OCR, 2D matrix, etc.) Barcodes: Code128A, Code128B, Code128C, Code39, Code93 2D codes: QR-Code, Data Matrix, Aztec-Code, Han Xin-Code Graphics, logos, symbols, etc. Linear, circular, angular, reverse, rotate sequential and batch numbering Automatic date, layered and time code; real-time clock |

| User interface | Control system: FCPilot Screen size: 10.1 inches |

| Communication and I/O interface | UDP, TCP/IP and RS232 Inputs for encoder and sensor |

| Standard and optional configurations | Standard: Marking machine, 10.1-inch external touch screen, fiber optic sensor, universal adjustment sensor bracket, hex tool kit (UV lasers are equipped with water cooling system). Optional: Photoelectric sensor, 2000 ppr encoder, encoder bracket, encoder wheel, fume extractor (single head), optional lenses (see “Marking area and working distance" in the table below for details). |

| Marking area and working distance | UV Focus Lens/100*100mm (Standard) UV Focus Lens/200*200mm (Optional) |

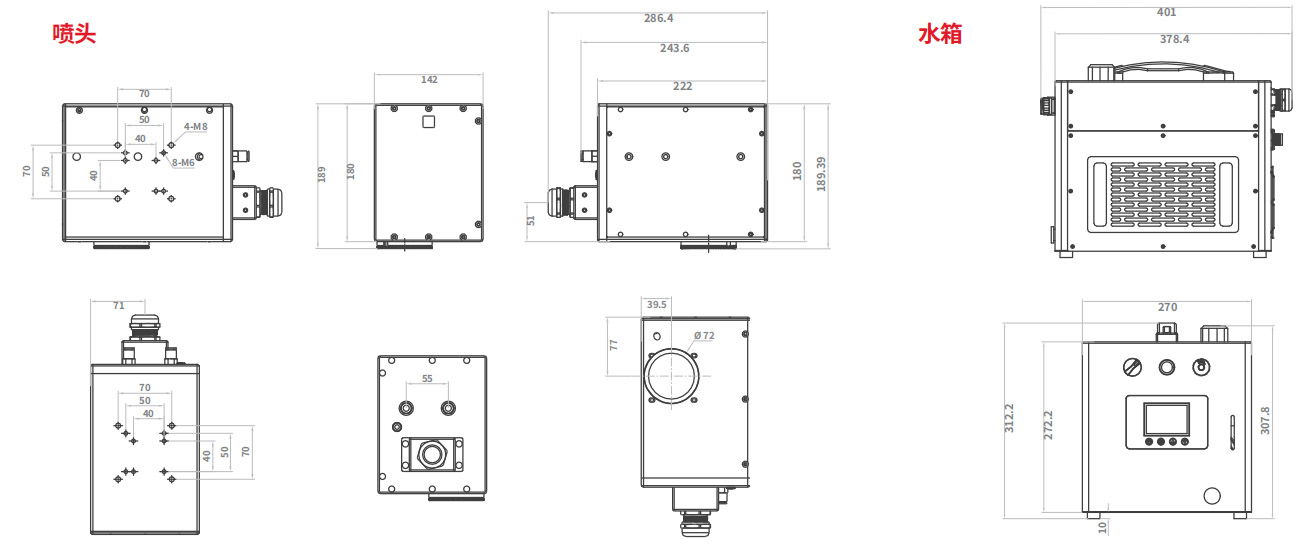

| Physical characteristics | Working temperature: 5-40°C (41-104°F) Humidity: 10%-90%, non-condensing Electrical requirements: 220 VAC, ~50/60 Hz, 1 PH, 750W Overall dimensions: see dimensional drawings for details Net weight: 24kg |

| Model selection | F7205U-T (5W UV laser marking system, Water-cooled) |

*Subject to the size/complexity of material and spray code information.

For product and application related matters, please consult FASTJET.

Product Dimensions (Unit: mm)